Volvo Fc2924c Excavator Workshop Service Repair Manual

- Repair Service Manual: 1771 Pages

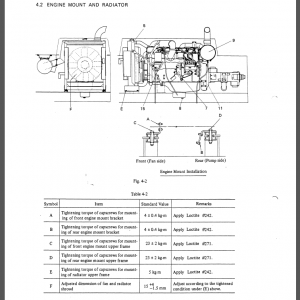

Specifications:

- Brand: Volvo

- Model: Fc2924c, D7E engine

- Type: Excavator

- Manuals: Repair Service Manual

- Publication Numbers: Ref. No 854441 7381

- Language: English

- Format: PDF

Engine, description

D7E – tier 3 compliant

The D7E configuration is a four stroke, straight six cylinder, turbocharged, direct injected diesel engine with charge air

cooling and wet, replaceable cylinder liners.

Table of Contents:

0 General

1 Standard Parts, Service

2 Engines with Mounting and Equipment

3 Elect. System, Warning System, Information System, Instruments

4 Power Transmission

5 Frame and Crawler Unit

6 Machinery House, Cab, Exterior Trim Parts Anywhere

7 Hydraulic System, Digging, Handling, Grading Equipment, Misc Equipment

Hydraulic and Electric schematics

Forestry quality. new keystone.

Volvo Fc2924c Given that 1927 the globally Volvo standard of value has been built around a cornerstone of quality. As a result, Volvo Building Devices has continued to be an international leader in development, top quality, efficiency, safety and security, gas performance and also ecological care. Now, brand-new higher standards of value and quality have actually been established with the introduction of the Volvo FC family members of purpose-built, tracked forestry providers.

These new forestry providers are made and created to the same demanding requirements that Volvo consumers around the world have involved expect and also depend on.

Volvo Fc2924c Excavator Workshop Service Repair Manual

tracked forestry providers is powered by a brand-new generation Volvo, turbocharged, EPA Rate III-compliant diesel motor with Advanced Burning Modern technology (V-ACT).

The D7E engine uses a Common Rail Fuel System controlled by the engine electronic control (E-ECU) software.

Electronically controlled IEGR (Internal Exhaust Gas Recirculation) reduces formation and lowers emissions without the

need for exhaust after treatment. Volvo’s latest engine management system, EMS 2 is used to control all engine electronic

functions.

The cylinders are numbered consecutively beginning at the flywheel end. Engine rotational direction is counterclockwise as

seen from the flywheel end.